Home-product:

excavator

Attention:

please click the following list, to check the details.

JCM series excavator

2016 Chinese Excavator Market:

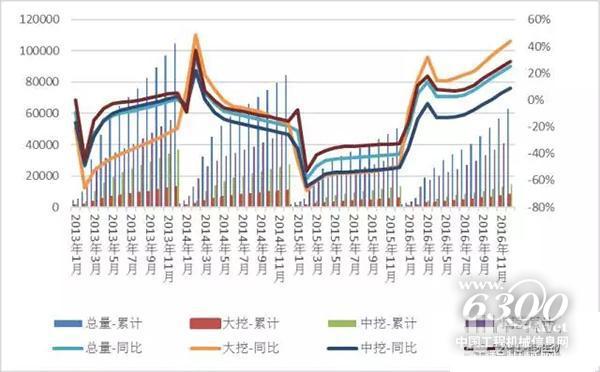

In 2016, the Chinese Excavator market total sold 62,899 units,

In 2016, Chinese Excavator An increase of 24.99% from the same period of last year.

In 2016, Chinese Excavator cumulative year-on-year growth of about 2% from the beginning of continuous improvement.

In 2016, Large-scale Chinese Excavator (tonnage ≥30t) sold a total of 7401 units, an increase of 44.13% over the same period of last year;

In 2016, Medium-sized Chinese Excavator (15t < tonnage < 30t) sales of 14,629 units, an increase of 8.08%;

In 2016, Small Chinese Excavator (tonnage ≤ 15t) sales of 40868 units, an increase of 28.75%.

Brief introduction of JCM excavator

Strong Construction Machinery Co., Ltd., a provincial state-owned enterprise, is the wholly-owned subsidiary of Shandong Heavy Industry Group. The company is established with the advantages of the excavator business of Shantui Construction Machinery Co. Ltd. and Shandong JCM Construction Machinery Co., Ltd., bearing the mission of expanding the excavator business of Shandong Heavy Industry Group. The main business includes the research, manufacture, sales, rental, and repair service of construction machinery, agricultural machinery, parts and microelectronic products; the export of self-managing products and the import of presenting products; the sales of hydraulic oil and lubrication oil; and the training of JCM excavator operation and repair.

At present, the company has two manufacturing bases respectively at Linyi and Jining with the investment of 5 billion Yuan, which have a total area of 720,000m2 and a planned annual output of 20,000 sets of JCM excavators. The manufacturing capability and technical level of the company all keep the lead in the industry. There are two product lines, JCM and GC products, among which, JCM has 11 specifications ranged from 6t-36t, and GC has 25 specifications ranged from 0.8t-68t. The market coverage of each product line is over 90%.

Strong Construction Machinery lays great emphasis on talent strategy. The company advocates to establish the humanistic environment centered on the concept of “forgiveness, communication, and responsibility”, and to set up a stage for employees to display their brilliance and realize their value of life. Now there is an abundance of excellent talent in the company.

The core concept of the company is “responsibility is weightier than Mount Tai.” And the sense of mission, achievements, belonging, social responsibility, national responsibility, and historical responsibility is the interpreting of the core concept.

“Keep the promise, and focus on quality” is our brand manifesto. We look on our promise to customers and the society as solemn as Mount Tai.

We firmly believe that, with the great support from the strong business platform -- Shandong Heavy Industry Group and the advantages in industrial collaboration, Strong Construction Machinery is sure to make brilliant achievements, and make great contributions to the sustainable equipment manufacturing group.

We’d like to cooperate with customers and partners to create beautiful future together.

Excavator Introduction:

Excavators are heavy equipment consisting of a boom, bucket and cab on a rotating platform (known as the "house"). The house sits atop an undercarriage with tracks or wheels. All movement and functions of the excavator are accomplished through the use of hydraulic fluid, be it with rams or motors. Their design is a natural progression from the steam shovel.

Excavators come in a wide variety of sizes. The smaller ones are called mini or compact excavators. Caterpillars smallest mini-excavator weighs 3549 lb (1610 kg) and has 19 hp; their largest model weighs 187,360 lb (84,980 kg) and has 513 hp. The largest excavator available is the Bucyrus RH400, it weighs in excess of 2,160,510 lb (980,000 kg), has 4500 hp and has a bucket size of about (52.0 m3).

Engines inExcavators drive hydraulic pumps; there are usually 3 pumps: the two main pumps are for supplying oil at high pressure (up to 5000 psi) for the rams, slew motor, track motors, and accessories, and the third is a lower pressure (700 psi) pump for Pilot Control, this circuit used for the control of the spool valves, this allows for a reduced effort required when operating the controls.

The two main sections of an Excavators are the undercarriage and the house. The undercarriage includes the blade (if fitted), tracks, track frame, and final drives, which have a hydraulic motor and gearing providing the drive to the individual tracks, and the house includes the operator cab, counterweight, engine, fuel and hydraulic oil tanks. The house attaches to the Undercarriage by way of a center pin, allowing the machine to slew 360° unhindered.

The main boom attaches to the house, it can be one of 3 different configurations, Most are Mono Booms, these have no movement apart from straight up and down, some others have a Knuckle Boom which can also move left and right in line with the machine, the other option is a hinge at the base of the boom allowing it to hydraulically pivot up to 180° independent to the house, however this is generally available only to compact excavators.

Attached to the end of the Boom is the Stick (or dipper arm), the stick provides the digging force required to pull the bucket through the ground, the stick length is optional depending whether reach (longer stick) or break-out power (shorter stick) is required. On the end of the stick is usually a bucket. A wide, large capacity (Mud) bucket with a straight cutting edge is used for cleanup and leveling or where the material to be dug is soft, and teeth are not required. A general purpose (GP) bucket is generally smaller, stronger, and has hardened side cutters and teeth used to break through hard ground and rocks. Buckets have numerous shapes and sizes for various applications. There are also many other attachments which are available to be attached to theExcavators for boring, ripping, crushing, cutting, lifting, etc.

Prior to the 1990s, all Excavators had a long, or conventional counterweight that hung off the rear of the machine to provide more digging force and lifting capacity. This became a nuisance when working in confined areas. In 1993 Yanmar launched the worlds first Zero Tail Swing excavator,[1] which allows the counterweight to stay inside the width of the tracks as it slews, thus being safer and more user friendly when used in a confined space. This type of machine is now widely used throughout the world.